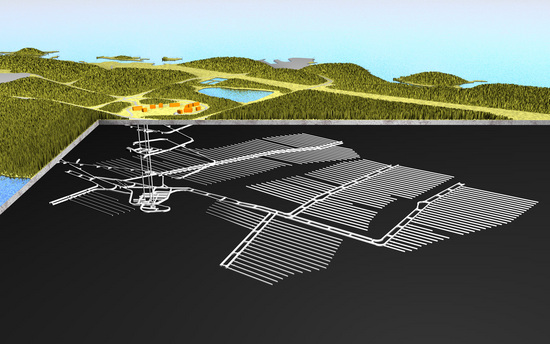

Data Centers – Main concern on reliability, availability and risk management

“In Finland there are currently large ongoing investments on targets that differ from traditional industrial projects. The amount of data centers required by IT and cloud services is increasing all the time and they are built e.g. into properties of closed paper mills. Execution phase is largely emphasized by life-cycle effectiviness, infrastructure availability and information security, without forgetting energy efficiency.”

Promaint article about the project (available only in Finnish): Asiakasprojekti: Konesalit

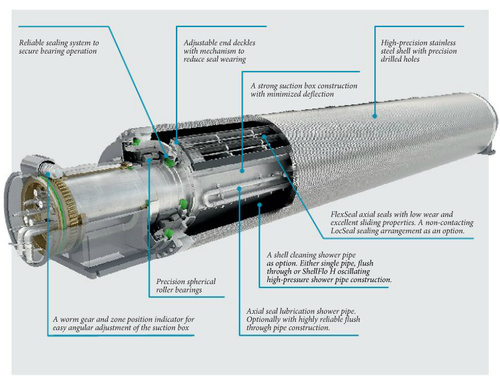

Dynamic simulation – Results from paper mill sheeting plant

“The production process of the sheeting plant is a very complex entity. By improving its operation it’s also possible to improve the overall productivity of the whole mill. With the help of dynamic simulation the bottleneck points of the production were located and the development actions were directed to the right targets.”

Promaint article about the project (available only in Finnish): Asiakasprojekti: Efora

Dependability analysis is an effective method for operations development

“Finnish Konecranes is one of the leading global providers of lifting equipment solutions and maintenance services. The company has been already years the technological pioneer of lifting industry. In the future the company strives to strengthen its position on the global markets. One solution for this is the development of preventive maintenance with the help of e.g. dependability and safety related RAMS analyses.”

Promaint article about the project (available only in Finnish): Asiakasprojekti: Konecranes

Availability risk recognition brought savings and renewed operation procedures

“With the help of process line dependability analysis it is possible to recognize the critical subsystems and to essentially improve the dependability. When process bottleneck points have been recognized, the renewing of operation procedures can produce cost savings of up to millions of euros achieved by decreased production losses.”

Promaint article about the project (available only in Finnish): Asiakasprojekti: Nokian Renkaat

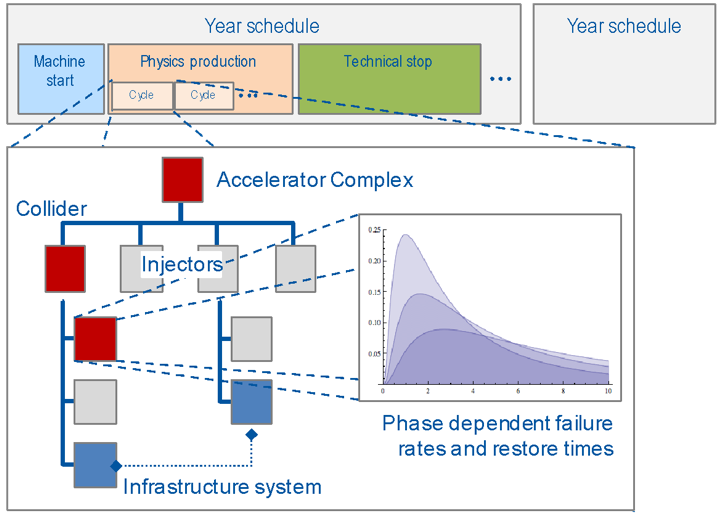

Optimizing maintenance of pulp mill startup with dynamic simulation model

“The pulp mill of Metsä-Botnia Rauma has taken into use in its post stoppage startups a dynamic dependability simulation model, that calculates an optimal startup curve based on the tank level situations.”

Automaation tehdaspalvelu article about the project (available only in Finnish): Asiakasprojekti: Botnia Mill Service

Reliability analysis as a tool for maintenance service business

“The industry sector is moving from maintenance work and failure repair to ensuring operation and managing overall dependability. This development leads to more demanding requirements concerning maintenance cost data, data collection, data refinement and operations predictability, whether the maintenance operations are handled by own organization or some external provider.”

Promaint article about the project (available only in Finnish): Asiakasprojekti: YIT

Monitoring product dependability – Field data as the basis

“The dependability requirements in the elevator and escalator industry have been growing steadily during the last years. The customers of KONE and the end users of KONE products have high expectations on the product availability. The amount of unexpected failures has to be minimized with the help of correct product design and effective maintenance. This challenge is very important considering both customer satisfactory and maintenance cost minimization.”

Promaint article about the project (available only in Finnish): Asiakasprojekti: Kone

Planning paper mill overall equipment effectiveness (OEE)

“The overall equipment effectiveness (OEE) of the process is defined as the product of dependability, performance and quality. It includes the effectiveness of both maintenance and production. When using paper mill as an example target the debilitating factors of OEE include paper mill stoppage time, decreased production speed occasions and lost production due to poor quality.”

Kunnossapito article about the project (available only in Finnish): Asiakasprojekti: UPM

ELMAS provides ABB the tools for reliability analysis

“Boliden Harjavalta Inc. and the plant dependability responsible ABB Service have a common goal: both want to be world-class performers at their own fields of industries. The tools for this on behalf of reliability technical analyzation are provided by ELMAS software that allows to describe the production process and the dependability related factors of its equipment, including e.g. root causes and cause-conequence relations. – ELMAS has brought a systematic policy and approach for dependability analysis, says the District Manager of ABB Service Jari Naukkarinen.”

An article about the project (available only in Finnish): Asiakasprojekti: Boliden ABB

StoraEnso acquires StockOptim for national use

“In many Finnish companies dependability is still based on the expertise and silent knowledge of some experienced maintenance operatives. In the future the people are still the ones making the decisions, but to support this decision making there is also mathematical facts available. Reliability, maintainability and supportability are factors that can be calculated and simulated.”

An article about the project (available only in Finnish): Asiakasprojekti: Storaenso

Fault tree software as a tool for reliability design of data terminal equipment

“ELMAS fault tree software has been in test use with the Enterprise Solutions sector group developing data terminal equipment. – Our products are very complex and their application environment therefore challenging for software like ELMAS, but for our reliability design ELMAS seems to provide a lot of benefits, states Kai Syrjälä, Director of Product Engineering at Nokia Mobile Devices Unit.”

An article about the project (available only in Finnish): Asiakasprojekti: Nokia

Reliability and maintainability engineering – a probabilistic approach

“Product reliability and maintainability are quality characteristics to which customers attach great importance when forming an opinion of the overall quality of the product. It is especially important to understand that these are precisely the characteristics whose design flaws cannot be fixed during manufacturing or operation. In fact it is in the product design phase where the fundamental decisions are made to set the maximum quality and minimum cost for the product. A company that has good control of the reliability and maintenance performance of its products has a considerable competitive advantage both in the case of design and manufacturing consumer products and when negotiating availability contracts for large industrial systems.”

Marine News article about the project: Customer project: Wärtsilä Marine